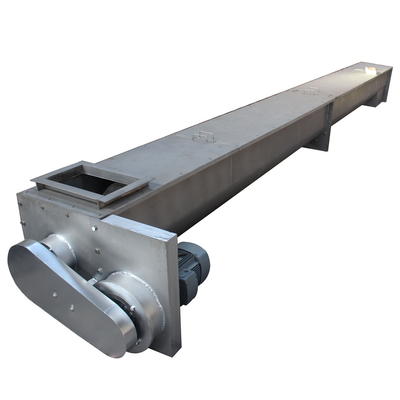

U Shaped Sawdust Screw Conveyor / U Trough Screw Conveyor

U Shaped Sawdust Screw Conveyor / U Trough Screw Conveyor is the main units for mechanical transport operation of various departments of industry and agricultures, screw conveyor can be used to reduce labor intensity and improve efficiency. The working temperature of the screw conveyor is usually -20 ~ 40℃, the temperature of the conveying material is generally -20 ~ 80℃, the screw conveyor suitable for horizontal and small angle arrangement, inclination to not exceed 15, if the tilt angle is too large please use GX series screw conveyor.

Application

U Shaped Sawdust Screw Conveyor / U Trough Screw Conveyor is widely used in building materials, metallurgy, chemical, electric power, coal, machinery, light industry, grain and food industry, suitable for conveying powder, granular, small pieces of materials, such as cement, coal, grain, chemical fertilizer, ash, sand, coke, etc. should not be easily perishable, viscous, easy to agglomerate the material. Commonly seen in the food industry, these conveyors transport ingredients to and from mixers, ovens and vats and need to be sterile at all times. Therefore, they are commonly made of stainless steel, a smooth food grade metal that is less likely to contaminate edible ingredients than other materials and is easily cleaned.

Specification

| Model |

Screw diameter |

Screw pitch |

n---rotation speed(r/min), allowable deviation<10% |

| Q---volume(m3/h), fill-factor=0.33 |

| (mm) |

(mm) |

n |

Q |

n |

Q |

n |

Q |

n |

Q |

| LS160 |

160 |

112 |

112 |

8 |

90 |

7 |

71 |

6 |

50 |

4 |

| LS200 |

200 |

100 |

100 |

14 |

80 |

12 |

63 |

10 |

50 |

7 |

| LS250 |

250 |

90 |

90 |

24 |

71 |

20 |

56 |

16 |

45 |

13 |

| LS315 |

315 |

80 |

80 |

34 |

63 |

26 |

50 |

21 |

40 |

16 |

| LS400 |

355 |

71 |

71 |

64 |

56 |

52 |

45 |

41 |

36 |

34 |

| LS500 |

400 |

63 |

63 |

100 |

50 |

80 |

40 |

64 |

32 |

52 |

| LS630 |

450 |

50 |

50 |

145 |

40 |

116 |

32 |

94 |

25 |

80 |

| LS800 |

500 |

40 |

40 |

208 |

32 |

165 |

25 |

130 |

20 |

110 |

| LS1000 |

600 |

32 |

32 |

300 |

25 |

230 |

20 |

180 |

16 |

150

|

Working Principle

U Shaped Sawdust Screw Conveyor / U Trough Screw Conveyor is rotating spiral blade for screw conveyor conveying the material goes on, the material is not spinning force with the blades of screw conveyor is its own weight and screw conveyor casing material for material friction screw conveyor on the axis of rotation of the welding of spiral blade, blade surface type according to the conveying material have different entity type belt type surface type, such as type of screw conveyor screw axis of vane surface terminal at the direction of material movement have thrust bearings to the material to spiral axial reaction force, when the captain a long, should add hanging bearing in the middle.

Features-U Shaped Sawdust Screw Conveyor / U Trough Screw Conveyor

1. Drive units mounted at inlet or outlet end.

2. Flanged end bearing assemblies protected against material infiltration by shaft seals.

3. Powder-coated.

4. Trough in standard length modular flanged sections.

5. Helicoid flighting welded on centre pipe.

6. Square or rectangular outlet spouts with integrated WAM standard drilled flanges.

7. Robust cast iron body flanged end bearing assemblies with externally positioned bearings and manually adjustable packed gland seals.

Advantages

1. The structure is novel, the technical index is advanced, the sealing device has little resistance, good abrasion resistance, low noise of the whole machine, good sealing.

2. The sealing is good and the shell is made of seamless steel tube. The end part is connected to each other by flanges and is rigid.

3. The application range of screw conveyor is very wide, suitable for conveying powdery materials.

4. Simple structure, low cost, small size, safe operation and can be sealed during operation. It's an ideal delivery device.

5. Large carrying capacity and safe and reliable.

6. Strong adaptability, convenient installation and maintenance, long life.

7. The machine is small in size and high in speed, ensuring fast and uniform delivery.

8. The machine has simple structure, small dimension, low cost and safe operation. It can meet the requirements of multi-point feeding and discharging according to process requirements.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!